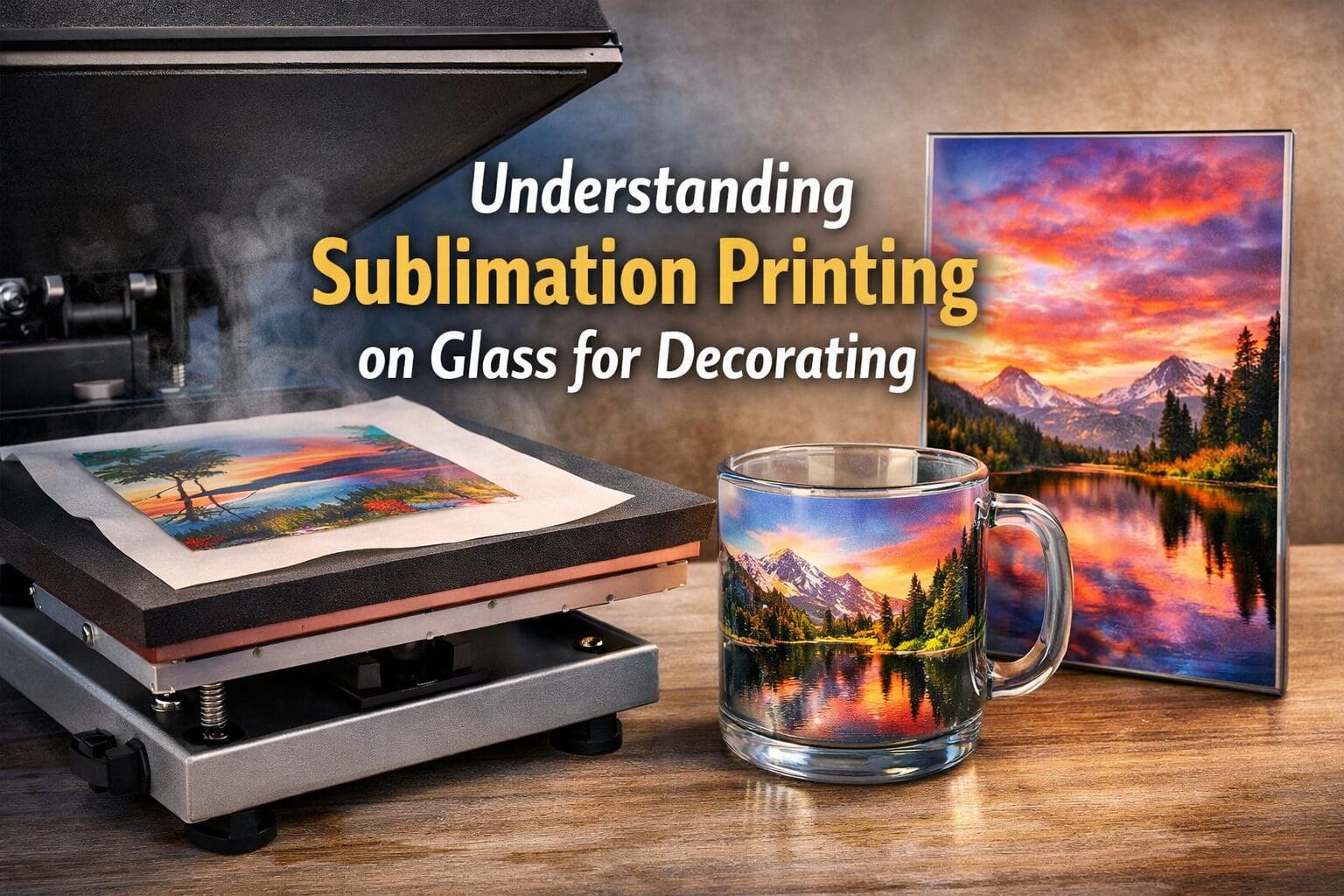

Sublimation printing is a widely used decorating process that allows detailed, full-color imagery to be applied to a variety of substrates. In recent years, it has gained increased attention in glass decorating, especially for applications where visual complexity, smooth gradients, and photographic detail are important.

To use sublimation printing effectively on glass, it is essential to understand how the process works, what materials are required, and how it fits within the broader landscape of glass decorating methods. This guide walks through the fundamentals of sublimation, its interaction with glass surfaces, and key considerations when evaluating it for decorative glass projects.

What Is Sublimation Printing?

Sublimation printing is a decorating method that uses heat and pressure to transform solid dye into gas. Rather than melting into a liquid, the dye sublimates, moving directly from a solid to a gaseous state. During this process, the gaseous dye bonds with a compatible polymer surface, becoming part of that coating once cooled.

This approach allows for high-resolution printing with smooth color transitions and minimal surface texture. Sublimation printing is commonly used where image clarity and color accuracy are priorities.

Because sublimation relies on molecular bonding, the receiving surface plays a critical role in the final result.

How Sublimation Printing Works on Glass

Glass is naturally non-porous, which means sublimation dyes cannot bond directly to untreated glass. To enable sublimation printing on glass, a polymer coating specifically designed for sublimation is applied to the surface.

This polymer coating acts as the receptive layer for the dye. When heat is applied, the dye sublimates and migrates into the coating rather than sitting on top of the glass. Once cooled, the image becomes locked into the coating layer.

This process allows glass to be decorated with:

- Full-color imagery

- Fine detail and gradients

- Smooth, continuous visuals

Sublimation coatings are a foundational part of successful glass decorating using this method.

Sublimation Coatings and Polymer Layers

Sublimation coatings are typically clear polymer coatings formulated to accept sublimation dyes. The quality and consistency of the coating directly influence printing clarity, color vibrancy, and overall appearance.

Important factors include:

- Coating thickness

- Cure consistency

- Adhesion to the glass surface

- Compatibility with intended use

Because the decoration resides within the polymer coating, proper coating application is essential for reliable results in sublimation printing.

Surface Preparation for Sublimation on Glass

Surface preparation is a key step in any glass decorating process, and sublimation printing is no exception. Clean, residue-free glass ensures proper adhesion of the polymer coating and consistent printing results.

Typical surface preparation steps include:

- Cleaning to remove oils or contaminants

- Controlled handling to avoid fingerprints

- Inspection prior to coating

Consistent surface preparation supports uniform decorating outcomes, especially when working with glass containers or drinkware.

Sublimation Printing in Glass Decorating Applications

Sublimation printing is used across a range of glass decorating applications, particularly where visual flexibility is important. It is often selected for projects that benefit from detailed artwork, complex color variation, or image-based designs.

Common applications include:

- Decorative glass panels

- Branded drinkware

- Promotional glass items

- Specialty glass containers

Because sublimation printing allows for design versatility, it is frequently considered during early-stage decoration planning.

Sublimation Printing vs Screen Printing on Glass

In glass decorating, sublimation printing and screen printing are often discussed together, as each serves different design and production goals.

Sublimation printing is well-suited for:

- Full-color imagery

- Photographic designs

- Variable artwork

Screen printing is commonly used for:

- Solid color graphics

- Logos and brand marks

- Repeating designs at scale

Both methods are established within glass decorating, and selection typically depends on artwork style, production needs, and intended use of the glass.

Sublimation Printing and Glass Containers

Glass containers are used across many industries, including home fragrance, beverage, beauty, and lifestyle products. When evaluating sublimation printing for glass containers, it is helpful to consider how the container will be handled, displayed, and used.

Sublimation printing allows decorative flexibility on glass containers and can support branding goals that require image-driven designs. As with any decorating method, alignment between design intent and decorating process supports successful outcomes.

Sublimation Printing for Drinkware

Drinkware remains one of the most recognized applications for sublimation printing on glass. The ability to apply vibrant, full-wrap designs makes sublimation an attractive option for custom drinkware projects.

Glass drinkware decorated through sublimation can feature:

- Multi-color graphics

- Seamless artwork

- Smooth surface finish

As with all glass decorating, evaluating the intended use environment helps guide process selection.

Suitability Considerations in Glass Decorating

Suitability is an important concept in glass decorating. Rather than one method being universally “better,” each decorating approach serves different functional and aesthetic goals.

When considering sublimation printing, suitability is often evaluated alongside:

- Artwork requirements

- Production volume

- Handling expectations

- Visual priorities

Understanding these factors helps ensure the decorating method aligns with the project’s goals.

Sublimation Printing Within Alternative Decorating Methods

Sublimation printing is one of several alternative decorating methods available for glass. Others include screen printing, spray coatings, and hybrid approaches that combine multiple techniques.

In many projects, sublimation is evaluated alongside other glass decorating options to determine the best fit for the desired outcome. This comparative approach supports informed decision-making and consistent results.

Glass Packaging and Decorative Flexibility

Glass packaging plays a significant role in brand presentation. Sublimation printing offers decorative flexibility that can support storytelling, seasonal designs, or visually complex branding.

By using sublimation coatings and controlled surface preparation, glass packaging can be decorated with detailed artwork while maintaining a clean, polished appearance.

The Role of Printing Quality in Sublimation

Printing quality is central to successful sublimation. Factors such as ink formulation, transfer accuracy, temperature control, and timing all influence the final decorated glass surface.

Consistent printing processes support:

- Accurate color reproduction

- Clean edges

- Predictable results across batches

These considerations apply to sublimation printing as well as other printing-based glass decorating methods.

Final Thoughts on Sublimation Printing on Glass

Sublimation printing is a versatile and widely used decorating method that enables detailed, full-color designs on glass when paired with the right coatings and preparation. By understanding how sublimation works, how polymer coatings interact with glass, and how printing quality influences outcomes, brands and designers can make informed decorating decisions.

Glass decorating is most successful when the decorating method aligns with the design intent, production needs, and end-use expectations. Sublimation printing remains an important option within the broader range of glass decorating techniques available today.