Sublimation has quickly become a go-to printing process for vibrant, full-color customization. Unlike traditional screen printing or heat transfer vinyl, sublimation allows for seamless, permanent designs that won’t peel or fade. It’s an ideal solution for creative teams looking to expand their product offerings into visually striking, durable glassware. But not all glass is suitable for this process—sublimation requires a poly-coated surface to bond properly, and the printing process involves high heat and pressure that only certain materials can withstand.

This guide explores the top 10 trending glass products you can sublimate, along with best practices for determining if sublimation is the right fit for your next custom printing project.

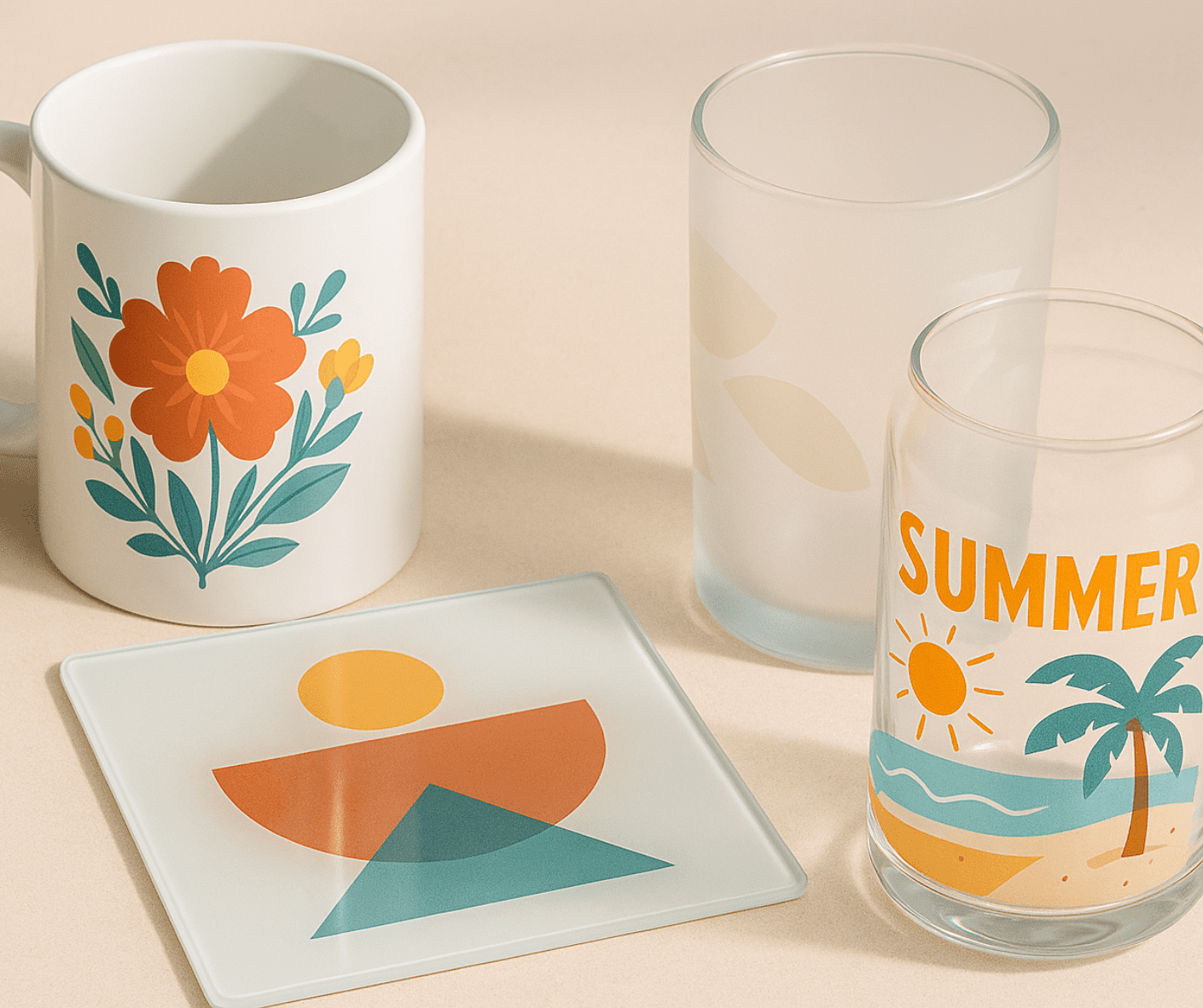

1. Frosted Sublimation Tumblers

Frosted tumblers are gaining popularity for their soft matte look and modern silhouette. These sublimation-ready drinkware pieces allow for partial transparency while showcasing colorful designs. When sublimated, they offer a smooth surface that diffuses the printed imagery in a subtle, sophisticated way.

Best practice: Minimalist designs with high-contrast colors tend to perform best on frosted surfaces.

2. Glossy Glass Mugs

Glossy sublimation mugs remain a staple in the custom printing market. Their coated surfaces deliver brilliant color results through dye sublimation, making them ideal for personalized gifts, promotional items, and brand merchandise.

Best practice: Pre-heating the mug ensures even transfer and reduces the chance of ghosting or print shifts.

3. Sublimation Wine Glasses with Frosted Bases

These hybrid vessels balance design and function by limiting sublimation to the frosted base or bottom half of the glass. The top remains clear for drinking visibility while the decorated lower portion enhances branding and aesthetic appeal.

Best practice: Keep printed designs on the bottom half to maintain product usability while showcasing color and texture.

4. Glass Ornaments

Sublimation glass ornaments are in high demand for seasonal promotions and commemorative keepsakes. Available in various shapes and sizes, these ornaments are fully customizable and deliver long-lasting imagery when printed with a sublimation printer.

Best practice: Apply a white underlayer to increase vibrancy, especially when working with transparent or lightly frosted substrates.

5. Sublimation Candle Vessels

Glass candle vessels offer a unique application for sublimation printing. When treated with the appropriate coating, these jars become the perfect surface for brand storytelling, patterns, and custom messaging that holds up to the heat generated by the candle inside.

Best practice: Use lighter sublimation tones that allow candlelight to glow through, enhancing both ambiance and design.

6. Gradient Ombre Bottles

Ombre sublimation is a trending effect for tall drinkware and decorative bottles. These sublimated gradients transition smoothly from one color to another, creating dynamic visual movement that elevates shelf appeal.

Best practice: Align color transitions with the natural curvature of the bottle to enhance the depth and flow of the final sublimation result.

7. Sublimated Glass Coasters

Flat, durable, and practical—glass coasters are an ideal format for sublimation. Their wide surface area makes them perfect for showcasing full-color logos, patterns, and artwork that resists scratches and daily use.

Best practice: Let coasters cool fully before removing the transfer paper to avoid blurring or shadowing.

8. Glass Can Shaped Mugs

With their soda-can shape and bamboo lids, these sublimation-compatible mugs have taken off in eco-conscious markets. The cylindrical body is perfect for full-wrap sublimation, making these mugs a canvas for colorful and detailed designs.

Best practice: Use tapered wraps or shrink sleeves for consistent pressure during the sublimation process.

9. Glass Picture Frames

Sublimated glass frames bring personalization to home décor. From full-bleed photography to commemorative branding, these frames showcase vibrant results thanks to their flat coated surfaces.

Best practice: Choose frames with coated inserts for optimal dye sublimation and long-term durability.

10. Decorative Glass Tiles

Sublimation tiles are used for signage, wall art, and interior design applications. When properly coated, they produce bold, high-gloss results ideal for both retail and custom decor.

Best practice: Center your design and avoid placing detailed elements near beveled edges to prevent visual distortion.

Is Sublimation Right for Your Product?

While sublimation opens up new possibilities in digital printing, it’s not the right fit for every project. Consider these key factors when deciding whether to sublimate your glass product.

Material Compatibility

Sublimation requires a special polymer coating on glass to properly bond the dye. Uncoated glass will not accept sublimation, no matter the pressure or temperature applied. Always confirm the substrate is compatible before running a production job.

Heat Resistance

The sublimation printing process reaches temperatures up to 400°F. The glass must be able to withstand this heat without cracking or warping. Testing is critical, especially when working with thinner-walled or uniquely shaped glassware.

Production Scale

Sublimation is most efficient at moderate to high volumes. While great for personalization and short runs, the setup and curing time may not be ideal for ultra-small batches. For very low quantities, alternative techniques like vinyl decals or direct screen printing might be more efficient.

Design Complexity

The ability to apply full-color, edge-to-edge designs is one of the strongest advantages of sublimation. However, designs must be carefully calibrated to account for curves, tapers, or transparency within the glass form.

Equipment Investment

Sublimating glass requires specific tools, including a sublimation printer, heat press or convection oven, sublimation paper, and compatible blanks. Evaluate your internal capabilities and potential return before scaling up.

Final Thoughts

Sublimation offers a versatile and high-impact method of customizing glass products. From mugs and tumblers to ornaments and tiles, the right sublimation-ready glassware can unlock bold creative possibilities and lasting impressions. When choosing which products to sublimate, focus on material compatibility, intended use, design scalability, and overall durability.

By applying best practices and understanding the nuances of the sublimation printing process, you can ensure your designs are not only visually compelling but also production-ready.