Why Color Accuracy Defines Product Quality

In glass decoration, color accuracy builds brand credibility. It determines how consumers recognize your products on shelves, online, and in packaging displays. When color shifts even slightly, the visual connection to your brand weakens.

Every hue you select tells a story about craftsmanship and attention to detail. At JAFE Decorating, that story starts in our paint lab, where each custom formula is designed for color stability that lasts through every production run.

Understanding Delta E (ΔE)

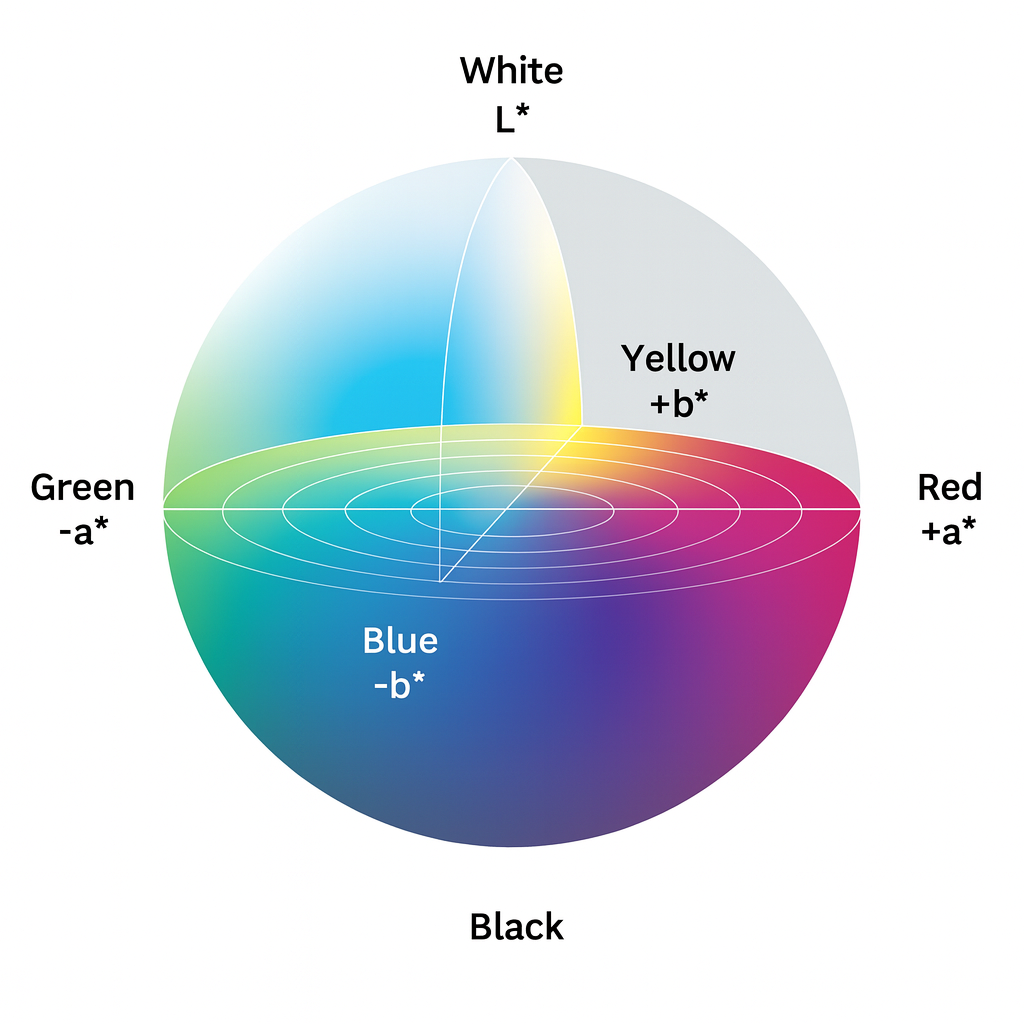

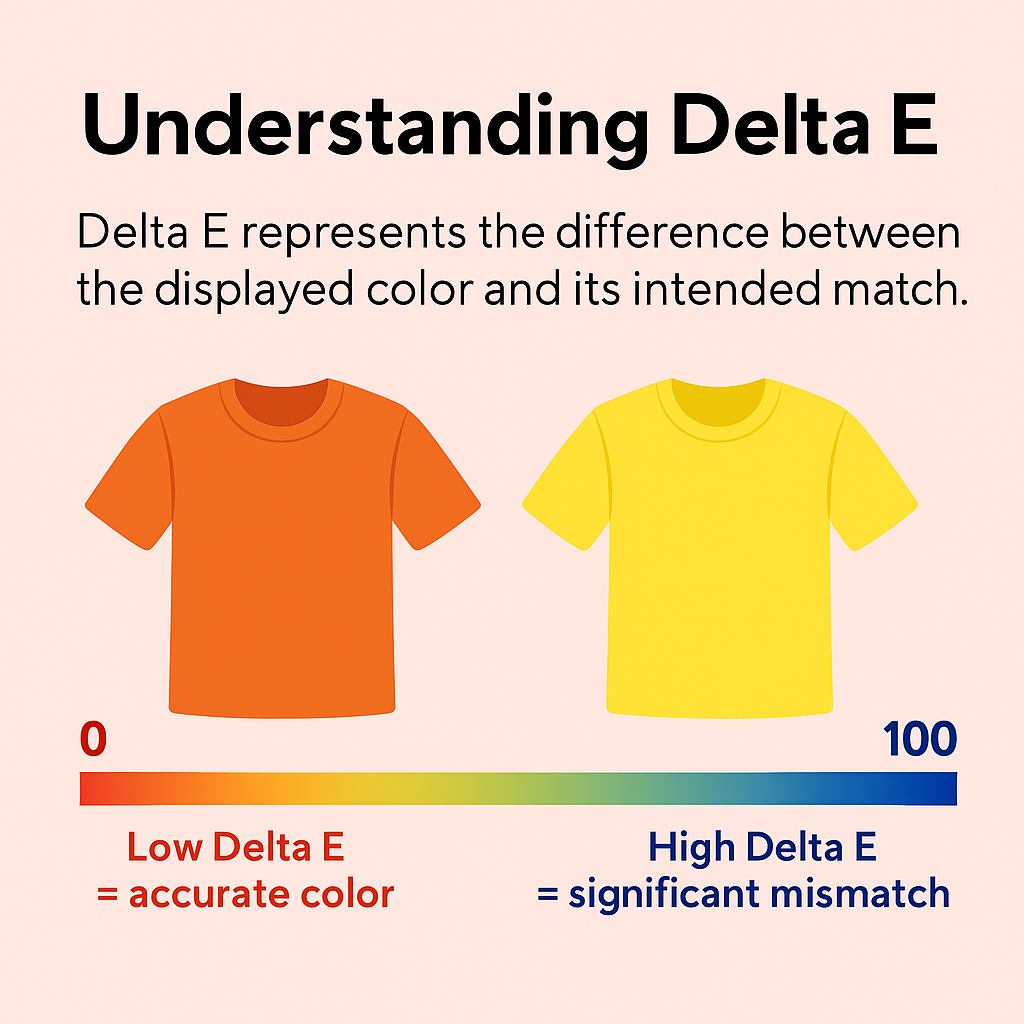

Delta E (ΔE) is the industry standard for measuring color difference. It represents the distance between two colors within the CIELAB color space, a system used globally to quantify color perception.

A ΔE value of 0 indicates an exact match, while values under 1 are so close that most people cannot see a difference. Maintaining ΔE < 1 ensures color consistency that meets professional-grade expectations for premium brands.

This precision guarantees that your candle jars, perfume bottles, or drinkware look the same from the first shipment to the hundredth. No visible variations, no rework, and no second-guessing whether your product will match the approved sample.

How JAFE Maintains ΔE < 1 Accuracy

Color control begins long before decoration reaches the production floor. Because JAFE creates paint in-house, our process eliminates the uncertainty that often comes from outsourcing.

- Spectrophotometer testing verifies that every batch meets internal standards before application.

- Real-time formula adjustments happen in our facility, allowing instant corrections if a color reads off-target.

- Immediate sampling keeps project timelines short, with approvals typically within 10 to 14 days.

With everything under one roof, our paint creation process removes delays and strengthens reliability for our customers.

The Customer Advantage

1. Consistency Across Every Order

When your brand color is consistent, customers instantly recognize your products. JAFE’s in-house system maintains visual harmony across collections, ensuring a cohesive look from season to season.

2. Less Waste and Rework

Accurate color matching reduces the likelihood of rejected batches. This helps minimize material waste, conserves energy, and allows your projects to stay on track without costly corrections.

3. Faster Turn Times

In-house production means we can move directly from formulation to testing without waiting for shipments. Projects stay in motion, and your products reach market faster.

4. Built-In Sustainability

Centralized color creation reduces freight emissions and packaging materials. Every avoided shipment contributes to a smaller carbon footprint and a cleaner process overall.

Why ΔE < 1 Matters for Business Growth

When color is measured and controlled precisely, it strengthens every stage of production. Designers can approve colors with confidence. Procurement teams can plan without delays. Retail partners receive consistent results across every order.

For large-scale production, that reliability protects your schedule and your brand reputation. For smaller brands, it opens the door to professional-quality decoration without large minimum order requirements.

JAFE’s paint system supports both, offering customization starting at 1,008 pieces while maintaining the same precision standards used for national brands.

Sustainability and Precision Go Hand in Hand

Creating paint under one roof reduces environmental impact in measurable ways. Each avoided shipment prevents unnecessary freight emissions and packaging waste. Higher first-pass acceptance rates also reduce energy use and glass waste that would result from rework.

Our sustainability approach is built into every stage of production, from material mixing to final inspection, helping our customers meet their own environmental goals while maintaining high-quality standards.

Confidence Through Control

When your decoration partner manages color creation, testing, and application within the same facility, you gain control over results that last. The consistency of ΔE < 1 gives you the confidence to focus on design and brand development, knowing that every finished product reflects the quality your customers expect.

Learn More About the Process

See how in-house paint creation improves speed, quality, and sustainability across every glass decorating project.

Download the whitepaper: The Case for In-House Paint Creation

Schedule a consultation: Discuss your next launch with our expert team.

Visit jafedecorating.com to explore our decorating, painting, and color control capabilities.